*** BUILT TO ORDER , 5 to 7 DAY Ship time **** Shipped in RTS Plastic Storage Case

RTS Center Sections are assembled by Professionals. Ford 9-inch third members are built from quality components with an exact step-by-step process. We bring this combination of precision assembly and quality components to you at a price that can’t be beat. We trust these third members so much, they’re the go-to choice for our own rides, from the street to the track.

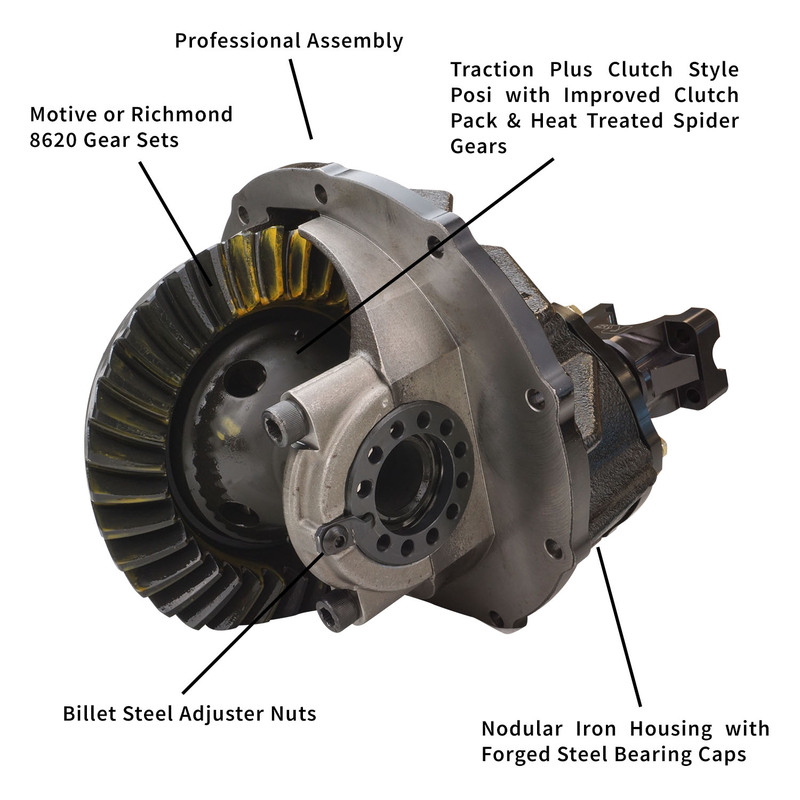

Tough, Nodular Iron Center Section

Our Ford 9 Inch Nodular Iron Third Member Center Section Carrier starts with a NEW casting with over 4 lbs. of additional material in critical areas. Nodular (ductile) iron is much more resistant to fracturing than OEM “gray” iron or painted black after assembled. Extra ribbing reinforces the case and rearmost pinion support (pilot bearing).

Thick, forged steel bearing caps surround the carrier bearings, all securely held in place with precision Grade 8 cap screws. The improvements continue with rugged billet steel adjuster nuts and heavy-duty keepers to ensure your ring gear settings are maintained. All mounting surfaces are precision machined to ensure a consistent, flat surface for a positive gasket seal (no more leaks on your shop floor). An oil fill plug is included.

Precision Assembled for Proper Ring Gear Teeth Pattern

Getting a proper pattern on the ring gear teeth is crucial. Our time-proven, step-by-step process ensures the correct backlash, preload, and proper amount of pinion shims to ensure the correct pattern on the ring gear teeth. Our gears use use cold-rolled 8620 steel, known for its long-wear and durability.

To ensure a proper gear pattern, we use our stronger Billet Aluminium Daytona” style pinion bearing support to maintain that critical pinion depth setting. Stronger due to its larger bearings, our Daytona pinion support also uses the spacer-and-shim setup to maintain critical pinion depth settings under high load, unlike traditional crush sleeves which often compress further, take out your preload and lead to failure. With solid bearing spacers and the proper shims, we eliminate this problem and make setting preload easy and repeatable during installation, service and gear changes. Since preload is already set, simply torque the pinion nut to 160 ft./lbs. and you’re good to go. The pinion gear is connected to our new, forged steel 1350 pinion yoke.

RTS Traction Plus systems are the latest design in differential tech upgrades. They combine the smooth operation of a limited-slip differential, with the strength of a fully machined case. These systems use carbon fiber and steel friction plate technology, delivering streetable and consistent traction. They arrive completely assembled--and because there are friction plates on machined internal gears, they are fully rebuildable. The carriers are the ideal solution for just about any light truck, sport utility, and muscle car on the road today.

- Works with factory 9 inch Ford differential case, gear, axles and bearings

- Spring loaded clutch pack with improved grip over OEM designs

- Forged steel case

- Heat treated spider gears

- Quiet operation, no clicking when disengaging for corners

- Ideal for street tires and medium horsepower applications

Proven Reliability

Our third member units are the go-to choice for our own rides and we have built these units to last with high quality hardware and components. Tapered steel roller bearings minimize friction, better handle thrust loads and increase load carrying capacity. The ring gears are assembled with Grade 9 bolts with a tensile strength of 180,000 psi, a 15% increase over Grade 8 hardware. Heavy duty Grade 8 carrier cap bolts, a lock-style pinion nut with pre-applied Loctite and high-quality grade 5 pinion support bolts make our third member near-bulletproof.

Our hand-assembled Ford 9 inch third member assemblies are made-to-order. We keep a supply of the most popular gears in stock, with most units built within 2-3 days.

Features

- Hand-assembled for an unbeatable combination of quality and value

- Precision assembly for the correct backlash, preload, and proper amount of pinion shims to ensure the correct pattern on the ring gear teeth

- Ring and pinion gears of 8620 cold-rolled steel for long wear which include brands like Motive or Richmond

- Nodular iron housing is stronger than OEM “gray” iron and has 4 lbs of additional reinforcement

- Large bearing “Daytona” style pinion bearing supports for strength and reliability

- Spacer and shim setup maintains critical pinion depth settings and easier to service than traditional crush sleeves

- Traction Plus Clutch style positraction differential gives limited slip performance and quiet operation (no gears clicking!)

- Ring gears assembled with Grade 9 hardware, 15% stronger in tensile strength than Grade 8

- Grade 8 Carrier cap bolts

- Lock-style pinion nut with pre-applied Loctite®

- Grade 5 pinion support bolts